Reducing our environmental impact

Wintershall Dea is aware of the impact its business activities have on the environment. As a responsible partner and operator, we know that protecting the environment is crucial. We assume our responsibility by setting high environmental standards and continuously working towards reducing the environmental footprint of our operations around the globe.

We track the movement of seabirds to assess environmental risks before carrying out drilling and production.

The future of the energy industry is low-carbon. At Wintershall Dea, it is our ambition to thrive while doing all we can to help solve today's greatest global challenge: meeting the world's growing energy needs while lowering CO2 emissions and fulfilling climate targets. Wintershall Dea is part of the solution and committed to being a leading company in carbon-efficient gas and oil production, providing secure and reliable energy.

As Wintershall Dea, we produce gas and oil as efficiently and responsibly as possible and aim to minimise our environmental footprint. As a company with operations around the globe, we take our part in climate and environmental protection very seriously. We assume responsibility by setting high standards and investing in technical innovation.

We stand for responsible extraction of gas and oil and professional risk management. We want to further reduce our environmental footprint, increase our transparency and promote technical solutions for environmental protection.

Climate approach

Rising energy demand requires expanding the many sources of our energy supply while simultaneously reducing the emission of greenhouse gases to slow down global warming and climate change. However, despite the rapidly growing share of renewables, they currently still play a subordinate role in the energy mix. This is why we expect that natural gas, the fossil fuel with the lowest CO2 footprint compared with coal or oil, will continue to play an important role in meeting the energy demand of the next decade.

Staffhorst is certified according to ISO 50001 energy management – as are all Wintershall Dea locations in Germany.

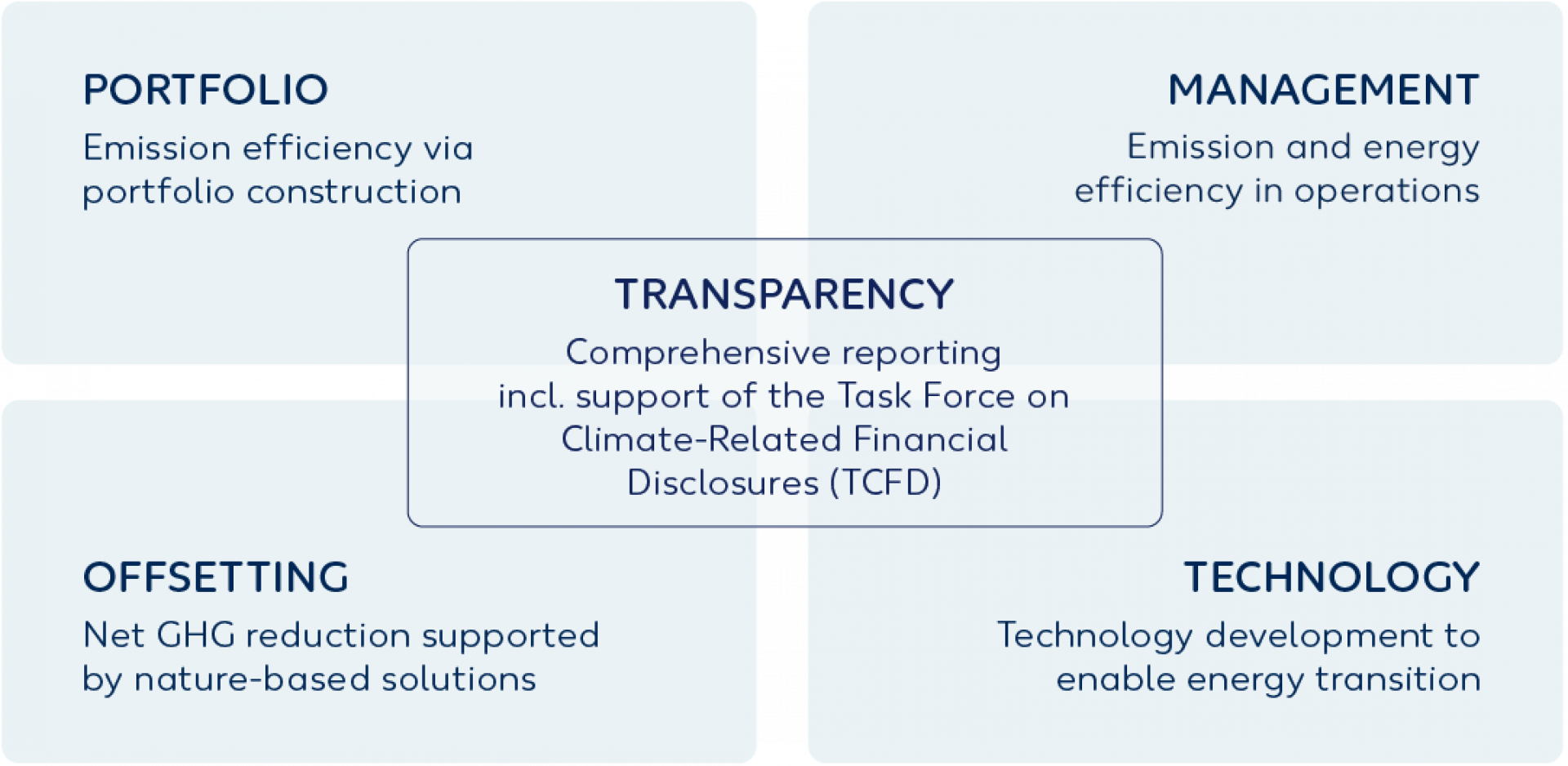

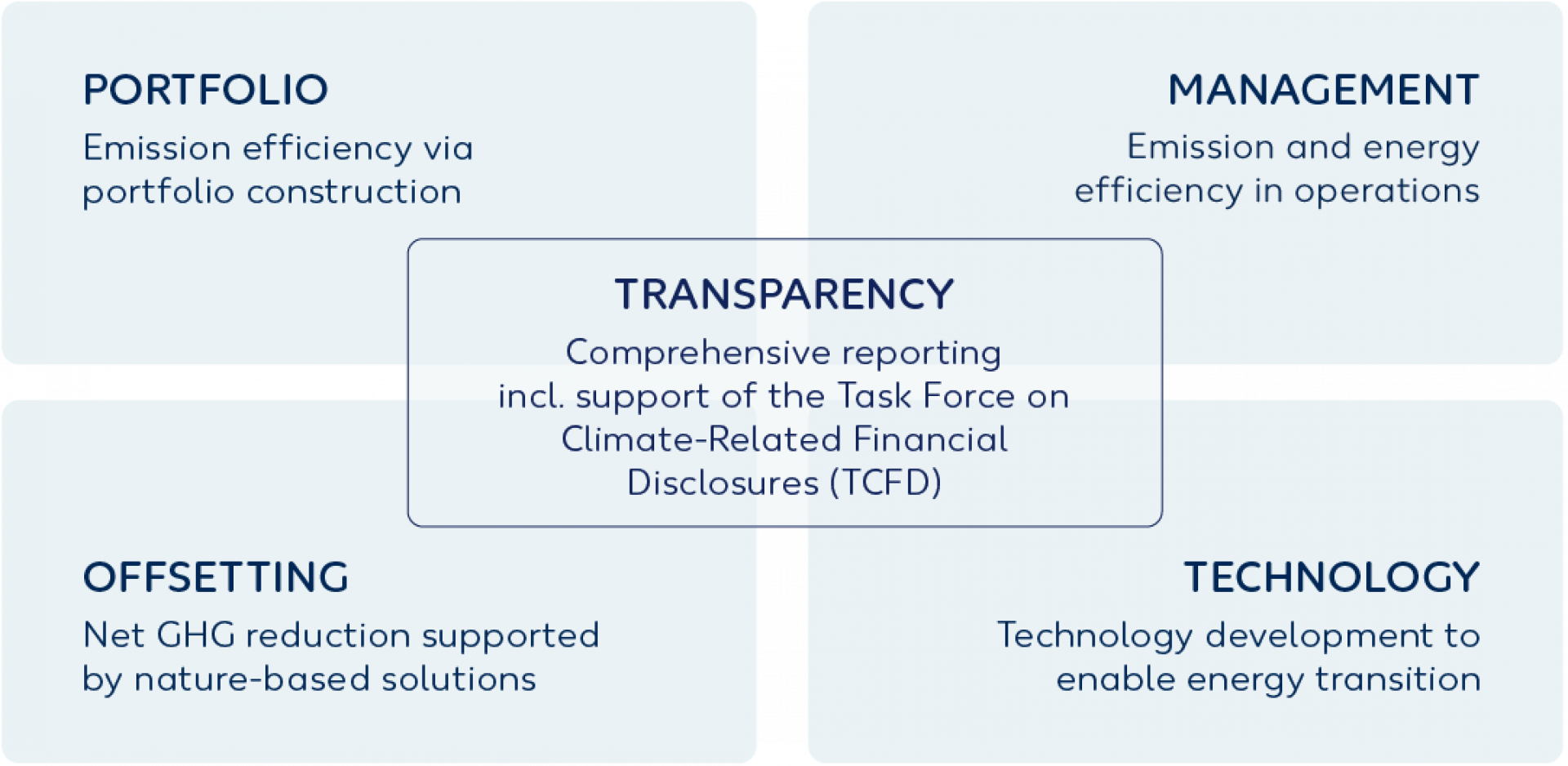

Our effort to protect our climate is based on four pillars

Our target is to reduce our Scope 1 and Scope 2 greenhouse gas emissions of our operated and non-operated upstream activities at equity basis and become net zero by 2030.

Since we strive to reduce emissions of greenhouse gases, natural gas will continue to be the main focus of our portfolio, currently accounting for 70% of our reserves and production. Using effective management, we want to increase our energy efficiency and reduce the direct emissions caused by our operations. We will continue to focus on research and development of innovative technologies to meet tomorrow's energy demands. Our approach is complemented by offsetting unavoidable emissions by investing in nature-based solutions, such as forestry projects.

Enabling the energy transition

In 2020, we set ambitious and measurable targets to further reduce our emissions and drive change. At Wintershall Dea, we are determined to play a key role in the energy transition and contribute to sustainable, responsible and profitable gas and oil production in a low-carbon environment.

Managing methane emissions

The Methane Guiding Principles focus on reducing methane emissions across the natural gas supply chain.

Lowering methane emissions is a very efficient way to reduce the overall greenhouse gas effect on the climate. As Wintershall Dea, we strive to reach near-zero methane emissions in operations and have set ourselves an intensity target of < 0.1 % for operated assets by 2025. We work closely with our industry partners to identify, quantify and mitigate methane emissions along the gas and oil value chain. Numerous industry activities, such as the Methane Guiding Principles where Wintershall Dea was a founding member, have successfully established platforms for cooperation, exchange and joint projects that target methane emission reduction. A sound knowledge of the emitted volumes is crucial to effectively reduce methane emissions. This is why Wintershall Dea fully supports Oil and Gas Methane Partnership (OGMP 2.0) led by the United Nations Environmental Program, which we joined in 2020. Transparency of the emissions related to natural gas extraction and transportation, coupled with technologies that further avoid and mitigate emissions will strengthen the role of gas as an important energy source during the course of the energy transition.

Our annual programme 2021 for the Methane Guiding Principles can be found here.

Innovations for the climate

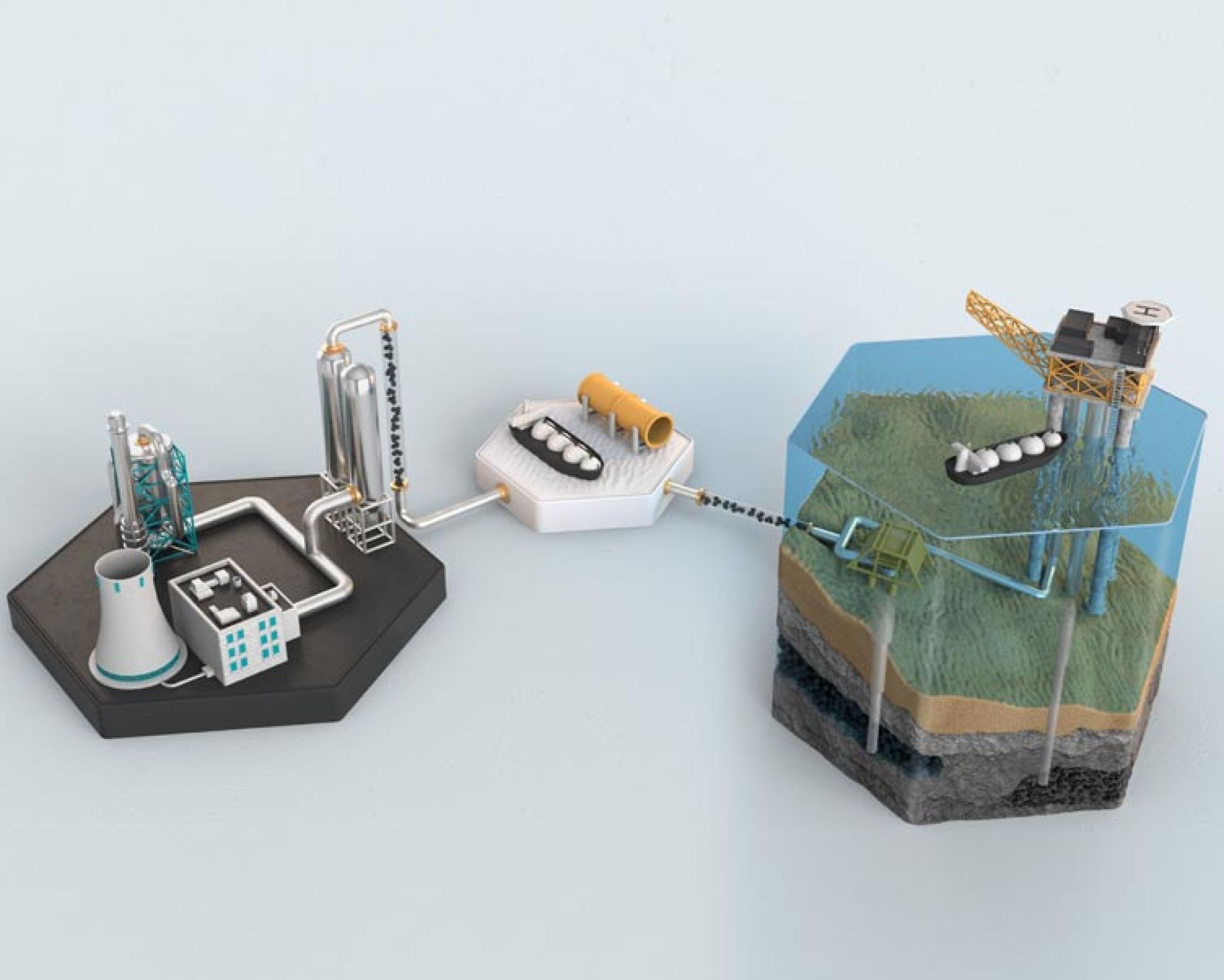

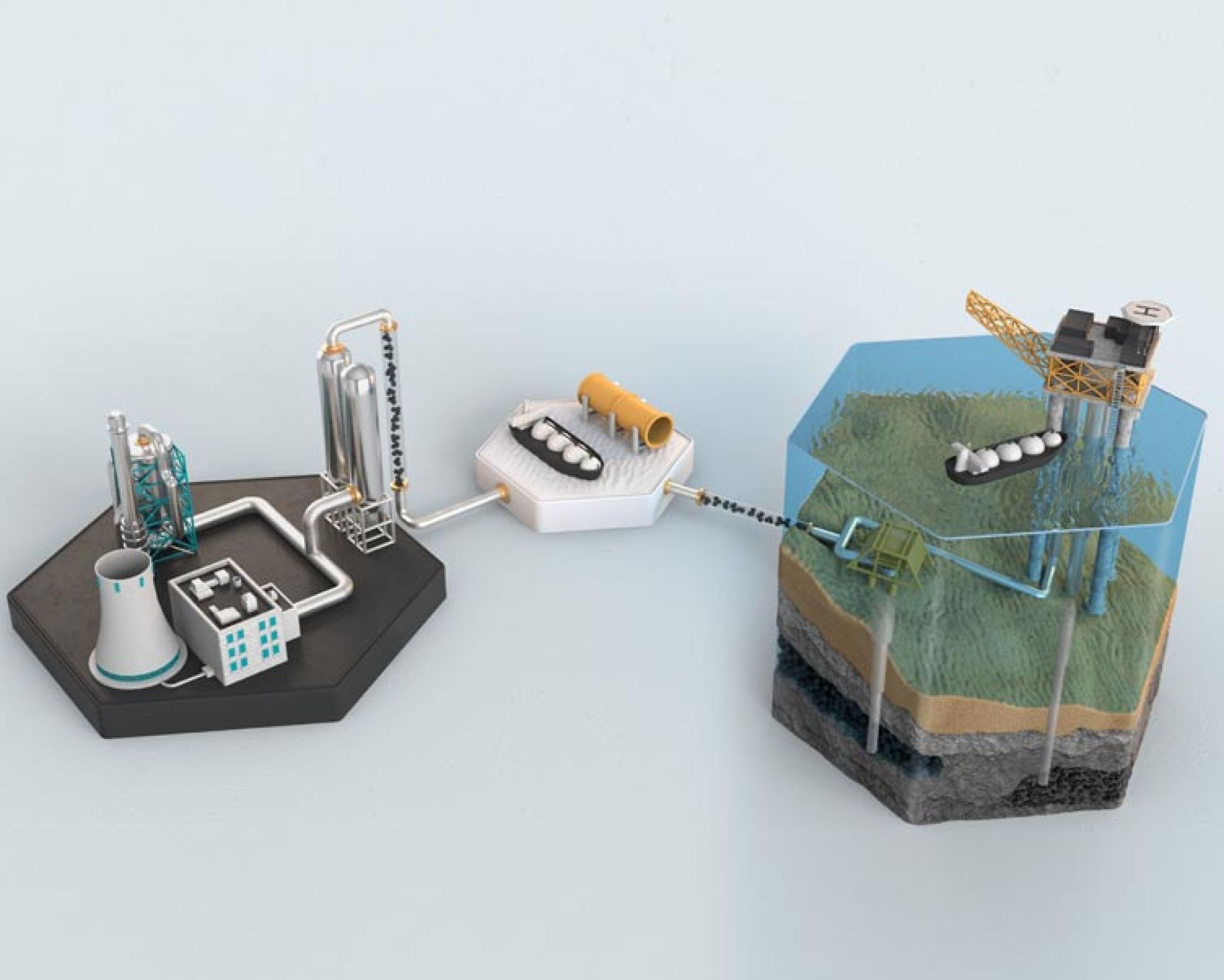

Wintershall Dea uses its E&P expertise on how to best handle CO2 to assess the suitability of its own CO2 storage reservoirs. In combination with CCS, the production of "blue hydrogen" by means of methane reforming will also support the battle against the climate with the captured CO2 safely stored in reservoirs. This will enable the delivery of decarbonised hydrogen, resulting in safe, affordable and reliable low-carbon energy, which is also being requested by our customers. CCS and hydrogen will offer new business opportunities and support our long-term future as Europe's leading independent energy company.

Model depicting carbon capture and storage in great depths.

Greensand project

Together with 23 project partners, the CCS project off the coast of Denmark aims to convert the depleted oil fields in the Siri Fairway into permanent and safe CO2 storage sites. The current phase 2 shall demonstrate a safe first injection of CO2 volumes. The first quantities of CO2 were already stored in March 2023.

Wintershall Dea and VNG invest in hydrogen project

Both partners have joined to invest in HiiROC as a pyrolysis technology partner. The company has also developed plasma technology to accelerate the cost-effective and CO2-free production of hydrogen. According to current plans, the pilot facility will go into operation in 2023.

HiirROC uses a new thermal plasma electrolysis process to produce low-cost, zero-CO2 hydrogen.

Mittelplate production island in the North Sea.

Mittelplate H2Move

Turquoise hydrogen shall be produced at the Dieksand facilities using associated gas from the Mittelplate production island by non-thermal plasma technology. The hydrogen will power the ships of a supply fleet to further reduce the CO2 footprint of Wintershall Deas's assets.

Researching turquoise hydrogen production

Wintershall Dea and the Karlsruhe Institute of Technology (KIT) are jointly researching how to produce "turquoise hydrogen" from natural gas. KIT is one of the largest research and educational institutions worldwide. The institute has already carried out fundamental research on producing hydrogen using direct methane pyrolysis based on liquid metal technology.

(f.l.t.r.) Thilo Wieland, former Member of the Board of Wintershall Dea, Professor Thomas Wetzel, KIT Institute of Thermal Process Engineering - Director, Dr. Leonid Stoppel, Karlsruhe Liquid Metal Laboratory and Dr. Timm Kehler, Chairman Zukunft ERDGAS, at the award ceremony of the Zukunftswerkstatt 2018.

Using renewable energy

Renewable energy sources help us to continuously reduce our emissions. At Wintershall Dea, we are switching to electricity generated by renewables at our production sites wherever possible. The change to renewables is a further step in implementing Wintershall Dea’s strategy to protect the climate by consistently reducing emissions. In Germany, Wintershall Dea has switched all production locations to certified electricity generated from renewable sources. In Norway, we participate in several projects to electrify gas and oil operations by using power from shore.

Mittelplate – green power from shore

Wintershall Dea has switched the power supply of Mittelplate drilling and production island in the Schleswig-Holstein Wadden Sea National Park to 100 per cent certified electricity from renewable sources. This makes Mittelplate the first oil field in Germany that runs solely on green electricity.

Video

Mittelplate, Germany's only drilling and production island is now powered by with 100 per cent certified electricity from renewable energy sources. Discover how the electricity is transmitted to the island.

Video

Mittelplate, Germany's only drilling and production island is now powered by with 100 per cent certified electricity from renewable energy sources. Discover how the electricity is transmitted to the island.

The Hywind Tampen offshore wind farm in the Norwegian North Sea will have a total capacity of 88 Megawatts and will help to cut CO2 emissions by more than 200,000 tonnes a year.

Hywind Tampen – floating wind power project

Wintershall Dea holds a share in Hywind Tampen, the world’s largest floating offshore wind farm in the Norwegian North Sea. The wind farm will supply offshore production platforms in the Snorre and Gullfaks fields with electricity, where Wintershall Dea also holds shares. Production is planned to begin in the third quarter of 2022.

Electrifying Edvard Grieg and Ivar Aasen

The ongoing electrification of the Edvard Grieg platform will soon be completed. Beginning of operations is scheduled for late 2022. This project will not only help to significantly reduce emissions from the field. It is already providing electricity to the neighbouring development area Ivar Aasen field. The Ivar Aasen development was electrified from the very beginning. Wintershall Dea holds shares in both projects.

The Ivar Aasen platform is located in the northern part of the North Sea, around 175 km west of Karmøy, Norway.

Offsetting approach

The path to significantly lower our emission of greenhouse gases is to avoid them wherever possible. When they can't be avoided at reasonable cost, we intend to compensate by investing in natural climate solutions, which is the third pillar of our approach.

Natural climate solutions provide a high degree of CO2 abatement, are cost efficient with benefits for local communities and indigenous people like improving their livelihood, contributing to the Sustainable Development Goals like biodiversity conservation and job creation. Our goal for the next years is to develop, together with selected partners, own projects and to constantly build and commercially manage a diverse offsetting portfolio including peat restoration, mangroves conservation and re- and afforestation with well-known carbon standards in Wintershall Dea’s core regions.

The Aguada Federal project in Argentina

Biodiversity conservation

At Wintershall Dea, we care about the regions where we produce natural gas and crude oil. Impact avoidance, mitigation and biodiversity offsets are used to ensure that the ecosystems are protected. Before we launch new projects or build new facilities, we conduct risk assessments and studies to examine the potential impact on the environment.

If possible, the first option is to avoid areas of high biodiversity value. By using minimum-footprint technologies, pre-existing habitats can be retained and secondary access can be limited. We strive to plan our activities to avoid or at least minimise negative impacts on the environment. Continuous upgrades of our biodiversity approach within operations allows us to spot potential impact, assess it and find the best solution available, so that mitigation rather than remediation is involved.

Turning a waste disposal site into a biotope

When Wintershall Dea cleans up and renaturalises formerly used areas, special attention is given to biodiversity. At our Emlichheim location, for example, we have turned the Holleberger Moor company waste disposal site into a biotope covering 50,000 square metres with areas of water and gravel islands.

In Emlichheim, sheep now graze on what was once a landfill.

Wintershall Dea supports the Norwegian research project SEATRACK.

Tracking seabirds

The research project SEATRACK charts the flight patterns of seabirds in the North Atlantic with the help of GPS trackers. The data is used, among others, by the Norwegian government and oil and gas companies like us. At Wintershall Dea, we use these findings to assess environmental risks before carrying out drilling and production.

Looking out for shelducks

In summer, large populations of European shelducks rest in the Wadden Sea. The birds regrow their flight feathers near to the Mittelplate drilling and production platform and are easily disturbed. We have been keeping track of the number of birds since 1988 so that our captains can avoid the areas where particularly large numbers of shelducks have settled.

At our Mittelplate location, the protection of the environment is right at the top of the priority list.

Water management

We strive for the conscious use and protection of natural water resources.

Handling of the world's key resource – water – responsibly is a central element of Wintershall Dea's day-to-day operations. We carefully assess the impact of our field operations on the area's water balance, including all water-bearing horizons. A special focus is placed on fresh water consumption and management in order to limit our impact and further reduce the use of fresh water by our assets.

Proper water management also involves being mindful of the water from deeper layers that is produced as a result of our gas and oil production. Our production water management is guided by very strict rules. We are fostering the implementation of new technologies to further improve water management, reduce fresh water consumption and limit our environmental footprint.

Waste management

The best waste management is not to produce any waste in the first place. This is why Wintershall Dea tries to create as little waste as possible, but during the exploration and production of crude oil and natural gas, it can't always be avoided. We comply with applicable local legislation in the classification, storage, treatment, transportation, and disposal of waste, in addition to international standards and those we set ourselves. In this way, we assure a disposal of waste in an environmentally friendly and appropriate manner.

The decommissioning of the Wintershall platform

K-10-b in the Dutch North Sea.

Oil spill prevention

For more than 30 years, the Mittelplate oil field has successfully combined environmental protection and crude oil production.

At Wintershall Dea, we take oil spills very seriously. Avoiding the uncontrolled release of the smallest amount of crude oil into the environment is one of our top priorities. We invest in innovative technology and preventive maintenance and always put safety measures in place to avoid leaks. In addition, our employees are trained to recognise leakage risks and perform risk assessments – ensuring a rapid response if a leak should occur. Our goal, as always, is to keep the environmental impact at a minimum. Leaks are repaired immediately or within a set time frame. We have prepared emergency and disaster plans and continuously train our employees, so that they can respond quickly and efficiently at all times.